Delphi to Supply DC-DC Converter & High-Voltage Wiring to New CODA Automotive All-Electric Sedan

Delphi Corp. announced that it will supply power electronics components, high-voltage electrical/electronic architecture components and a multi-service antenna for the all-electric, four-passenger sedan due out from CODA Automotive later this year. The California-based company joins a long list of hybrid and electric vehicle manufacturers who have chosen to work with Delphi on their environmentally friendly vehicles.

"Delphi has a track record of more than 20 years of innovating alternative energy technology," said Andrew Brown, Jr., Ph.D, Delphi Executive Director and Chief Technologist. "The growing hybrid and electric vehicle markets allow us to fulfill our vision of delivering the high-value, real-world solutions that consumers are demanding. We are honored to have been chosen by CODA to supply their first all-electric car with the important electrical and electronic content it requires."

CODA’s electric vehicle is designed and engineered at its headquarters in Santa Monica, California It is powered by a 33.8 kWh lithium-ion battery which provides a range of 90-120 miles. CODA anticipates it can deliver more than 14,000 vehicles to customers in California by the end of 2011.

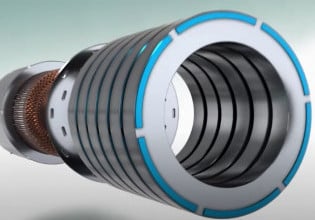

Delphi states that its direct current to dc-dc converter met CODA’s need for an automotive-grade dc-dc converter that was high quality, safe, durable and available immediately. Designed and manufactured in Delphi’s Kokomo, Indiana facility, it converts 300V power from the CODA’s battery pack to 12V power needed for the vehicle’s low-voltage systems including the audio/navigation systems, LED driving lights and other accessories. The design is currently in use on hybrid vehicles offered by a number of manufacturers.

Delphi engineers in North America and China worked together to develop the ten high-power, high-voltage wiring harnesses and two power distribution boxes that will stand up to the vehicle’s power requirements to route power and signal distribution. Delphi’s battery service disconnect provides manual disengagement of the high-voltage system, allowing it to be safely disabled by pulling the service plug from the battery pack.

"Delphi began working on the foundation of modern hybrid technology more than 20 years ago," Brown said. "Our global footprint and long history of successfully developing and commercializing automotive electronics and electrical/electronic architecture positions us well to support today’s hybrid and electric vehicles."